In our FAQ we have collected the most frequently asked questions by customers. Please browse through the answers and contact us for support if you should have any further questions. We are glad to help!

A guidance to the terminology and general information for test sieves and equipment for particle analysis.

Overview of ASTM E11 sieve designations, conversion table as well as corresponding Endecotts equipment.

Overview of ISO 3310-1 test sieve designations, nominal aperture sizes as well as corresponding Endecotts equipment.

Sieves and Calibration FAQ

Endecotts manufactures full height and half height test sieves. The height (depth) of the sieve is the height of the upper frame from the rim to the bottom of the sieve.

The following sieve diameters are available in half height: 100 mm, 200 mm, 300 mm, 8 inch, 12 inch

Extra deep sieves are also available for these diameters: 200 mm, 450 mm, 8 inch

Yes, all Endecotts test sieves are manufactured to a National or International specification and are supplied with Certificate of Compliance free of charge.

Other levels of certifications are also available upon request.

Endecotts offers affordable re-inspection and re-certification services of your existing woven wire mesh test sieves.

Please attach all relevant documents to the outside of the package in a suitable envelope with a SAFETY DECLARATION. The declaration needs to state the sieved test material and confirm that the sieve has been thoroughly cleaned.

Due to our internal Health & Safety regulations we cannot open the package unless your documents are attached on the outside.

Please contact customer service for pricing and download the Safety Declaration for your printer.

Endecotts has compiled handling and cleaning instructions for test sieves and microplate precision sieves:

PLACEHOLDER FILES PLUGIN:

CLEANING GUIDE

Each sieve is unique and manufactured according stringent quality control. Therefore Endecotts test sieves cannot be repaired due to their construction and design (manufacturing procedure).

The damaged sieves will need to be replaced with a brand new one. Also, the mesh cannot be replaced individually.

Contact us for a free quote on your replacement.

Endecotts calibration samples are microspheres formed of soda-lime glass that range from 3.35 mm down to 20 microns. Because of the precise nature and extent of the range of spheres, samples can be supplied to enable the accurate calibration of individual sieves to an accuracy of approx +/- 1µm.

The microspheres pass over, almost, the total surface of the sieve enabling more apertures to be examined than with any other method. Consequently, calibration samples are one of the most accurate and reliable methods of sieve calibration available.

Please view the Calibration Samples page for instructions and details.

PLACEHOLDER FILES PLUGIN:

CALIBRATION GUIDE

The Material Manufacturing Declaration provides details on the precise composition of Endecotts test sieves:

PLACEHOLDER FILES PLUGIN:

MATERIAL COMPOSITION

The size of a test sample for test sieving is largely governed by the density and size distribution of the particles.

To find the best sample size for your application, please consult our Test Sample Size Guide:

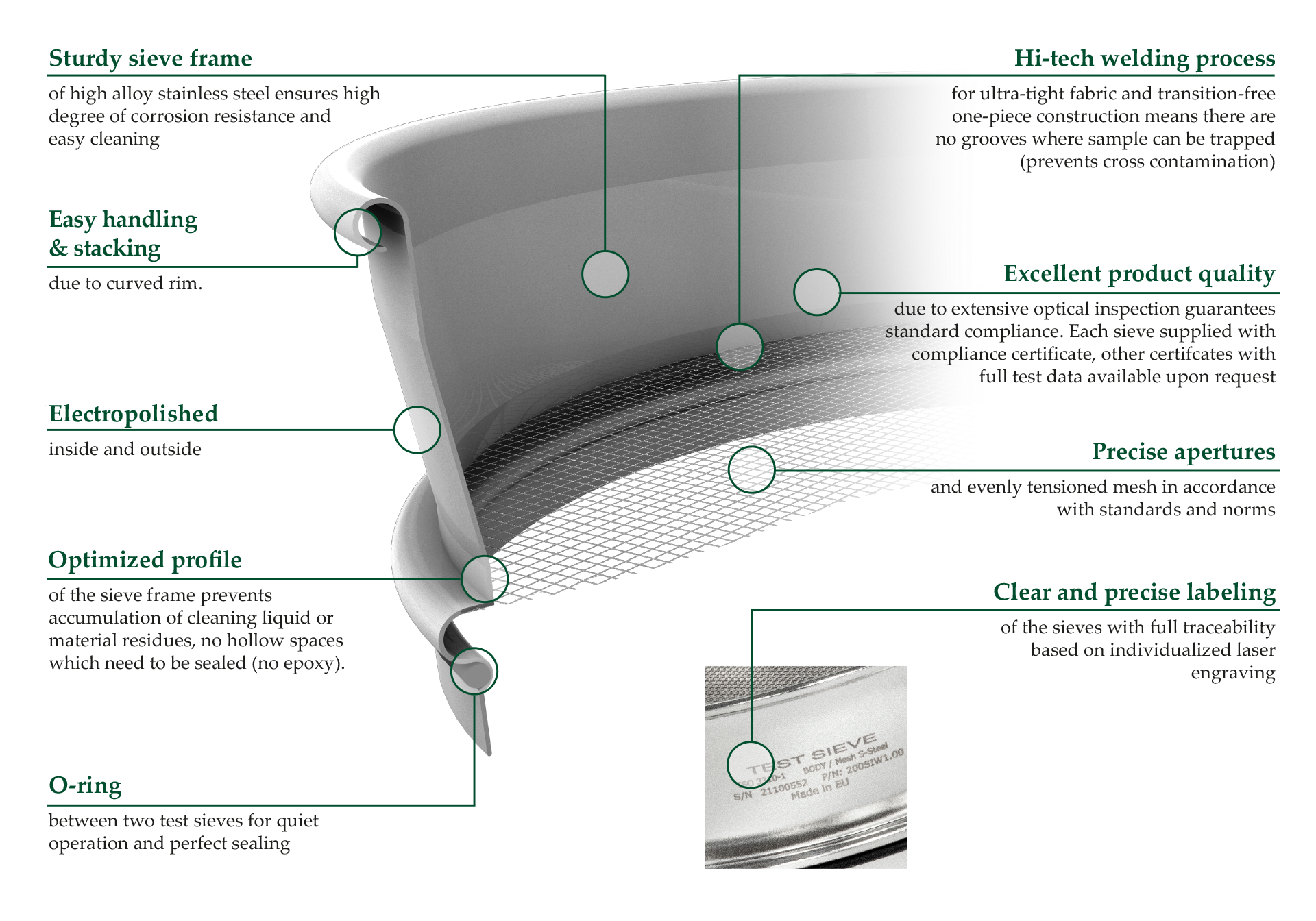

Endecotts sieves are individually made under the most stringent quality control procedures using only the finest materials.

The wirecloth is checked at every stage of manufacture either by optical projection or highly sophisticated computer scanning techniques. The final inspection is a precision measurement of apertures and sieve frame dimensions. Only when we are satisfied it meets our exacting standards do we give it an Endecotts 'Certificate of Conformity'.

Key features of Endecotts sieves include the following:

Endecotts offers two types of air jet sieves: “Standard” and “Premium”.

“Standard” air jet sieves are available with a diameter of 200 mm (8" on request).

“Premium” air jet sieves are available with a diameter of 8".

The Air Sizer 200 is only compatible with “Premium” air jet sieves with 8" diameter.

For most size analyses it is usually impracticable, and indeed quite unnecessary, to use all the available screens in any Standard Sieve Series.

Please read our Choice of Sieve Sizes guide for details:

PLACEHOLDER FILES PLUGIN:

CHOICE OF SIEVE SIZES

Sieve Shakers FAQ

All Endecotts sieve shakers can be used for wet sieving, except the Minor 200 and Air Sizer 200.

If you need the smallest sieve shaker for dry and wet sieving we recommend the Octagon 200.

To equip any sieve shaker for wet sieving, however, you always require a wet sieving conversion kit.

Yes, a demonstration is possible and you can bring your own sample for a test sieving.

For further information please visit the Application Laboratory.

Most sieve analyses are performed dry, but there are some applications which can only be carried out by wet sieving. It is very important not to change the sample in its volume (no swelling, dissolving or reaction with the liquid).

Most sieve shakers are able to carry out wet sieving, but you will need a special wet sieving conversion kit. Please note that Endecotts wet sieving kits are suitable for Endecotts sieve shakers only.

A wet sieving kit includes a top clamping plate with a Perspex cover and spray rose, watertight seals and a stainless steel receiver with drainage spout.

To operate the Air Sizer 200 you require the airjet machine, a vacuum unit, an airjet lid and sieves with special airjet design.

The Air Sizer 200 is supplied with the plexi glass cover. Vacuum unit and airjet sieve(s) need to be ordered separately.

For available mesh sizes, please consult our Air Jet Sieves.

If you purchase an Endecotts sieve shaker, the following is included:

Shaker base, stainless steel rods, clamp plate, handles and UK/European lead.

The sieve shaker does not include sieves, lid or receiver; they need to be ordered separately.

When ordering a shaker, please advise the voltage, frequency and power plug in order to supply you with the correct setup.

Because of the excellent quality of Endecotts sieve shakers there is no routine maintenance required.

It is recommended to keep the unit clean by regularly wiping it down with a soft, damp cloth.